Factory Dark Spots & Peppering

Share

Factory dark spots are typically a byproduct of the manufacturing process, typically minute particles trapped inside the MCP or other manufacturing layers, dark spots of various sizes are inevitable and quite literally, magnified when assembled into a night vision device.

Most night vision output screens measure roughly 18mm in diameter but through a night vision eyepiece, any imperfection is magnified several times to almost fill your complete vision. While nobody wants to see any spots in their field of view in their night vision, intensifier manufacturers have enacted specific standards when it comes to the maximum number of spots that can be allowed in any given zone.

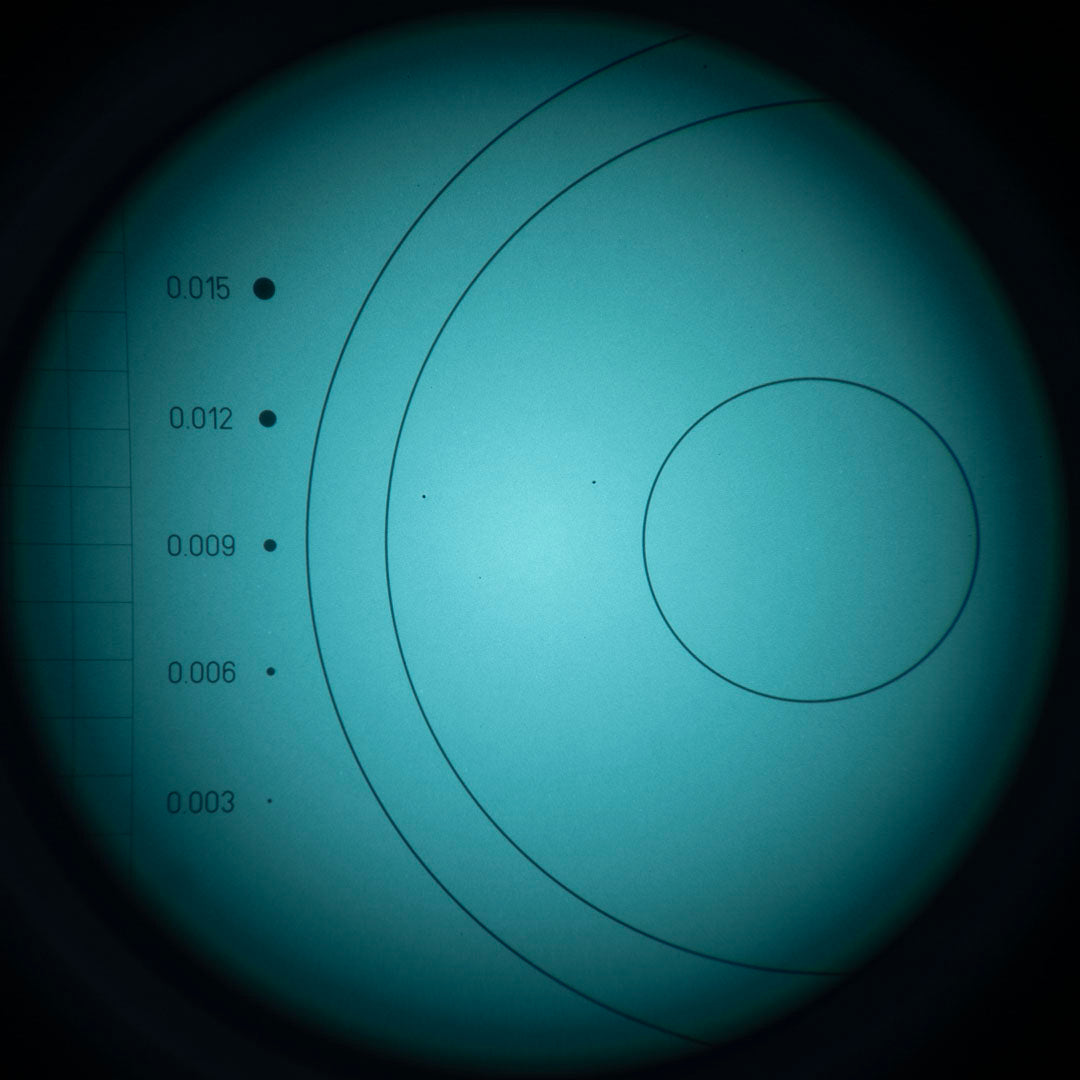

The following image below shows the typical Hoffman zone chart with a number of reference spots along with their corresponding spot sizes.

It can be observed that there are two spots just on the cusp of about the same size as the 0.003" (yes that's 0.003 inches in size) reference spot in the centre of the image, with the remainder of the image being relatively clean.

Referencing the spot tolerance for Photonis Echos below, it can be concluded that the 2 spots roughly 0.003" in size actually fall within the spot tolerance of Zone 1. Any spots smaller than 0.003" are not classified as spots and are generally referred to as "peppering". Peppering exists on every intensifier tube and it's only a matter of whether your eyes are sharp enough to detect them which can be very difficult, given their size. While it has been rare to see an intensifier approach the maximum spot tolerance per the zone chart below, it is certainly possible and users should bear this in mind when selecting or otherwise passing on certain intensifiers.

| Spot Size | Zone 1 | Zone 2 | Zone 3 |

| 0.009" - 0.012" | 0 | 1 | 2 |

| 0.006" - 0.009" | 1 | 2 | 4 |

| 0.003" - 0.006" | 2 | 4 | 6 |

But what does this translate to in real-world conditions? Taking this same tube outdoors, shown below is a typical scene.

So what is the takeaway? While large spots >0.009" and up can be very visually distracting, smaller spot sizes such as the ones shown at 0.003" typically blend into the image and become far less noticeable in a practical sense. When reviewing through-tube photos such as the ones showing the zone chart, it can be very easy to get fixated on screen quality, but how often are you staring at blank white walls? Intensifier manufacturers keep the general usability of their tubes in mind and that's why all tubes must fall within the specified spot thresholds.

As a last step, we also conduct a spot spec analysis using our Hoffman test rig which measures the spot size via image analysis, removing subjectivity.